|

Pulling fertilizer out of thin air with solar

power

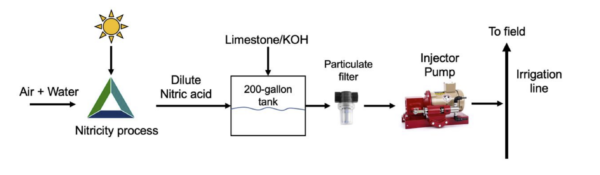

Nitricity has put together an experimental plasma reactor that uses

solar electricity to produce competitively priced, environmentally

clean, nitrogen fertilizer. Their onsite fertilizer production

eliminates emissions from transporting fertilizers, and provides a

viable alternative to fossil consuming nitrogen fixation methods like

the Haber-Bosch process.

January 18, 2022

John Fitzgerald Weaver

Image: Nitricity

Nitricity is using solar electricity to extract nitrogen directly from

our air to produce nitric acid, the most critical nutrient in

fertilizer that plants use to grow everything we humans eat. The key

features of the company’s product are the decarbonization,

decentralization, and privatization of fertilizer manufacturing, made

possible by affordable, off-grid, intermittent solar electricity.

Process

The company installed its first commercial project in

October of 2021. The off-grid solar power system is

composed of 144 solar panels, though details describing the solar

hardware were scant.

On their website, Nitricity shares an

experimental report on their pilot project in Fresno,

California. The initial installation’s solar system was a 16-panel

ground-mount array that outputted 75-85 V with a maximum power of 2.4

kW.

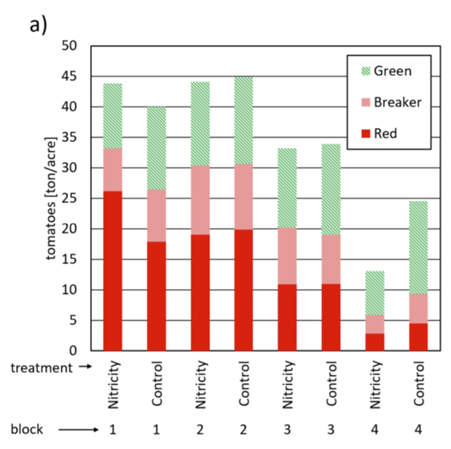

The installation was coupled directly with a sub-surface irrigation

system used to fertigate a tomato crop. The paper covers the apparent

success of their hardware, which produced tomatoes in a volume and

quality that were similar to the control tomatoes. (The control

tomatoes received a standard, industrially produced nitrogen

fertilizer.)

Pilot project

Nitricty believes that their product will fill several niches. Because

the system is easily distributed, farmers located far from fertilizer

manufacturing centers will have additional financial incentive to try

out the new technology.

Nitricity’s process directly competes with industrial ammonia

production – a process which directly creates more CO2

than any other human driven chemical process on earth. The

primary feedstock for modern nitrogen fixation is natural gas. The

processing of the gas into ammonia releases these emissions. The

chemical process emissions are only part of the story, as the

emissions released from the fossil fuels traditionally used to heat

and sustain the reaction are also excessive.

In its favor, the Haber-Bosch process was largely responsible for the

Green Revolution of the middle 1900s, which helped catapult the global

population. It is estimated that nearly

half of all nitrogen currently found in human tissue was

produced using this process.

Additionally, Niticity’s distributed, localized nitrogen solution also

avoids transportation emissions. The company points out that market

inefficiencies related to the distribution process of fossil-sourced

nitrogen fertilizers can increase a farmer’s fertilizer cost as much

as two to five times above the costs at a factory. Fossil-based

fertilizer production costs are also volatile due to their direct

relationship with natural gas – which, as mentioned earlier, supplies

the primary feedstock for industrial ammonia.

Project results

In December, the US Department of Energy’s

ARPA Energy awarded the group $500,000 to advance their

“non-thermal plasma reactor” process. ARPA notes that, “literature and

modeling analysis suggest that an energy efficiency ten times better

than present plasma values and equal to or better than that of the

conventional Haber-Bosch process could be achieved”.

In

an interview with Agrifood Conversations, the company noted

that the intermittent nature of solar power is not only easily

managed, but is actually a desired trait. According to one of

Nitricity’s founders, Nicolas Pinkowski, the process “operates better

intermittently. Because we manufacture nitrates (NO3-), there is a lot

of oxygen to transport per lb of nitrogen”. Nitricity uses a 200

gallon tank to store the product prior to it being applied to the

tomatoes.

In August of 2021, the company raised $5 million. Recently, Nitricity

announced that it signed a deal with a wheat producer by releasing

some emissions-focused math:

-

1 acre of wheat

needs about 100 lbs of nitrogen.

-

100 lbs of N (via

ammonia or urea) are produced in a coal- or NG-fired factory today,

emitting ~300 lbs CO2.

-

~1.5 lbs of N2O are

emitted per acre via the nitrification process. This means one acre

emits approximately 450 lbs CO2 due to soil N2O emissions.

-

In total, 1 acre of

wheat can emit as much as 750 lbs CO2 emissions from fertilizer

production and application.

Nitricity’s technology mitigates nearly 100% of these emissions.

It could be that these fertilization systems will integrate with

solar powered greenhouses and other

responsible land management techniques. In doing so, solar

power will likely prove to be indispensable to our future food

production.

Green Play Ammonia™, Yielder® NFuel Energy.

Spokane, Washington. 99212

www.exactrix.com

509 995 1879 cell, Pacific.

Nathan1@greenplayammonia.com

exactrix@exactrix.com

|