|

18

August 2023

By

Nathi Magubane, University

of Pennsylvania

Researchers develop new

carbon-capture solution for a cleaner, more energy-dense fuel source

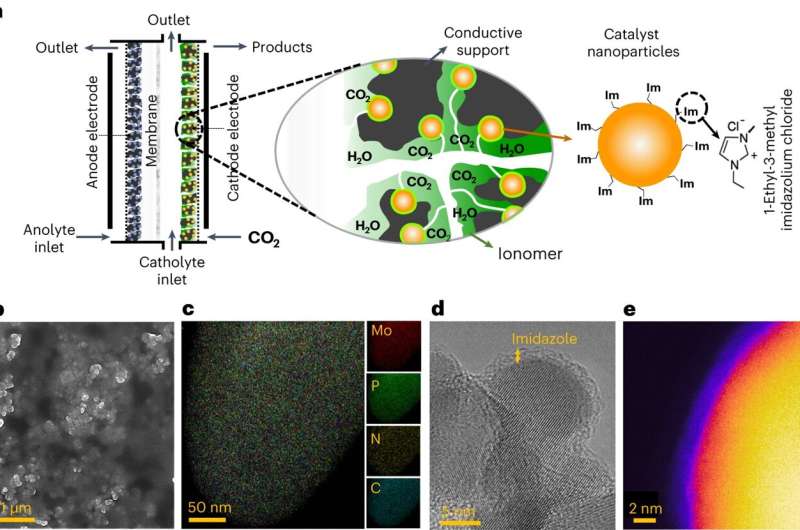

Characterizations of the catalyst

microenvironment of the developed ImF-Mo3P electrocatalytic system

studied in a flow electrolyser. a, Schematic of the catalyst

microenvironment composed of Mo3P nanoparticles covered by an Im layer

coated with an anion-exchange ionomer and deposited on a conductive

carbon support. b, SEM image of the cathode electrode coated on the

gas diffusion layer. c, TEM-EDS mapping image of the catalyst

microenvironment. EDS mapping of Mo, P, N and C elements are shown

with red, green, yellow and blue colors, respectively. d, TEM image of

the dispersed nanoparticles in the catalyst microenvironment. e, False

color EELS image of a single ImF-Mo3P nanoparticle. This image

suggests an Im layer of about 1 nm. Credit: Nature Energy (2023). DOI:

10.1038/s41560-023-01314-8

Over the past three centuries, especially since

the Industrial Revolution in the late 18th and 19th centuries, human

activities have significantly increased greenhouse gas levels in the

Earth's atmosphere. The main culprits are fossil fuel consumption,

industrial processes, deforestation, and waste management.

In response, the United States aims to cut greenhouse gas

emissions by 50 to 52% from 2005 levels by 2030. This initiative

aligns with a global effort to achieve net-zero greenhouse gas

emissions by 2050. With electric power and industry sectors

contributing to about half of U.S. carbon dioxide (CO2) emissions,

finding solutions in these areas is imperative.

Now, in a paper published in Nature Energy, researchers from

the University of Pennsylvania, Illinois Institute of Technology, and

the University of Illinois at Chicago have developed a system that can

convert CO2 emissions into propane (C3H8), a cleaner, more

energy-dense fuel source.

"Electrochemical conversion of CO2 can serve future energy

needs by storing renewable energy and closing the anthropogenic carbon

cycle," says co-author Andrew Rappe of the School of Arts & Sciences

at Penn. "This research paves the way to new solutions that will

tackle energy storage challenges and meaningfully reduce CO2 levels."

"Making renewable chemical manufacturing is really important,"

says co-author Mohammad Asadi of Illinois Institute of Technology.

"It's the best way to close the carbon cycle without losing the

chemicals we currently use daily."

Copper has traditionally been the go-to element for researchers

investigating efficient ways to convert CO2 into valuable chemicals

and fuels, both to curb its environmental impact and provide new

energy storage solutions. However, the fuels produced have been

low-energy density single-carbon compounds like methane.

"Getting energy-dense multi-carbon products like C3H8 has

remained a challenge due to the many intermediates that form

throughout the chemical conversion process," explains Zhen Jiang,

co-first author of the paper and a former postdoctoral researcher in

The Rappe Group. "Additionally, most strategies to increase a

material's selectivity for multi-carbon molecules tend to be

energetically costly."

Jiang says that the team sought ways to move beyond existing

catalysts like copper—and their modest selectivity for multi-carbon

products or their sluggish kinetics—and investigated ways to add ionic

liquid (IL) into the catalytic system. This prompted the team to look

at tri-molybdenum phosphide (Mo3P) as the catalytic material.

"Based on our theoretical simulations, we found that the IL

layer can enhance the adherence of CO2 and subsequent groups during

reaction on the Mo3P catalyst surface, thus stabilizing the

intermediates at different sites along the surface to produce C3H8

with an unparalleled efficiency of 91%," says Jiang.

The team also notes that this key finding led to a new paradigm

for exploring the relationship between materials in electrocatalytic

systems.

"Conventionally, the solid-state catalyst, and the aqueous

solution that bridges ion transfer throughout the reaction acted with

less mutual promotion at the interface," says Jiang. "But now, we can

apply a hybrid approach via techniques like IL coating on solid-state

catalysts and re-examine previously tried systems with our novel

understanding of the catalyst's microenvironment."

Looking ahead, the researchers plan to build on this research

in two ways: one, to develop a catalog of ionic liquids and their

effectiveness in fuel-generating catalysts and other electrochemical

systems; and two, investigate new catalysts for the conversion of CO2

into more energy-dense fuel sources from fuel gas to light oil with

more carbon atoms.

Rappe says, "Extending this research to higher-weight

hydrocarbons could close the carbon cycle by creating natural gas,

propane, gasoline, and even jet fuel directly from the CO2 made by

previous fuel combustion. In this way, the same carbon atoms store

energy over and over, and we don't release them into the atmosphere."

Green Play Ammonia™, Yielder® NFuel Energy.

Spokane, Washington. 99212

509 995 1879

Cell, Pacific Time Zone.

General office:

509-254

6854

4501 East Trent

Ave.

Spokane, WA 99212

|